EASE 5 - Precise and powerful room acoustic optimizations

One of the main objectives in the development of EASE 5 is to enable intuitive and fast creation and adjustment of a representative and precise room model. The reasons are simple: On the one hand, time can better be spent on detailed evaluation, optimization and further planning, and on the other hand, any simulation can only be as good as the model is accurate.

Accurate room modeling

Creating a model that reproduces acoustically relevant aspects of the room as accurately as necessary cannot be estimated highly enough when it comes to room acoustic predictions and planning specifications. In this respect, for example, the surface geometry as well as the choice of materials have an important influence on the acoustic properties of a room.

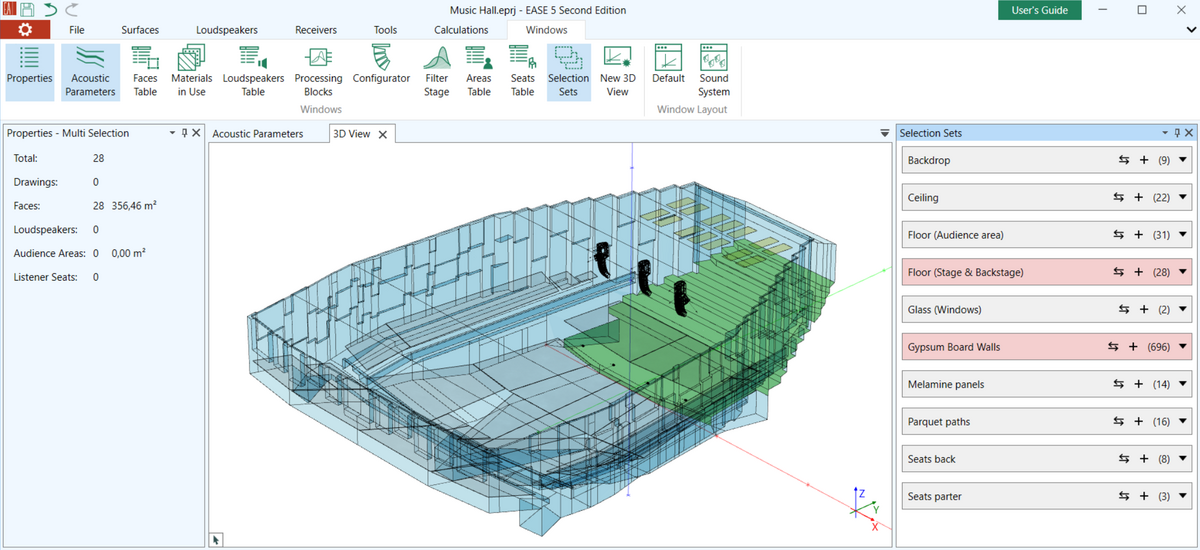

The user-friendly CAD editor of EASE 5 offers all the necessary tools to model and adjust these two aspects in an easy and intuitive way. As far as room modeling is concerned, functions for snapping, moving, duplicating, rotating, extruding, subtracting, joining of faces, as well as toggling visibility are available, ensuring the effortless creation and editing of surfaces. Organizing and modifying faces in the room is significantly facilitated by grouping with selection sets. They provide an overview of the number of faces and the total area of associated surfaces (also available for multi-select). Selection sets additionally enable convenient handling of material assignments, may it be while drawing the room or after importing layer-based CAD files. In this way, the reverberation time of the room can be easily evaluated, adjusted and optimized.

When it comes to fine-tuning the model, preparing it for the simulation, and fixing potential errors, several tools and views help finding potential geometrical problems in the model.

One can, for example

- Check for holes and face orientation via the room volume indicator and "Hole Outlines" function,

- Use the x-ray and wireframe views to better understand the 3D structure of the model,

- Switch to parallel perspective to verify model consistency using standard view directions,

- Create cutting planes to see cross sections of the model,

- Use Solid Rendering mode to see the model in its original colors for easier understanding of potential modeling mistakes.

Material assignment

For assigning materials, EASE version 5 provides an extensive, reviewed database of materials for ceilings, walls, and floors. It includes a number of categories, namely the materials loaded in the current project, a small generic database designed by AFMG, a large curated database collected by AFMG and a user-defined database with custom materials.

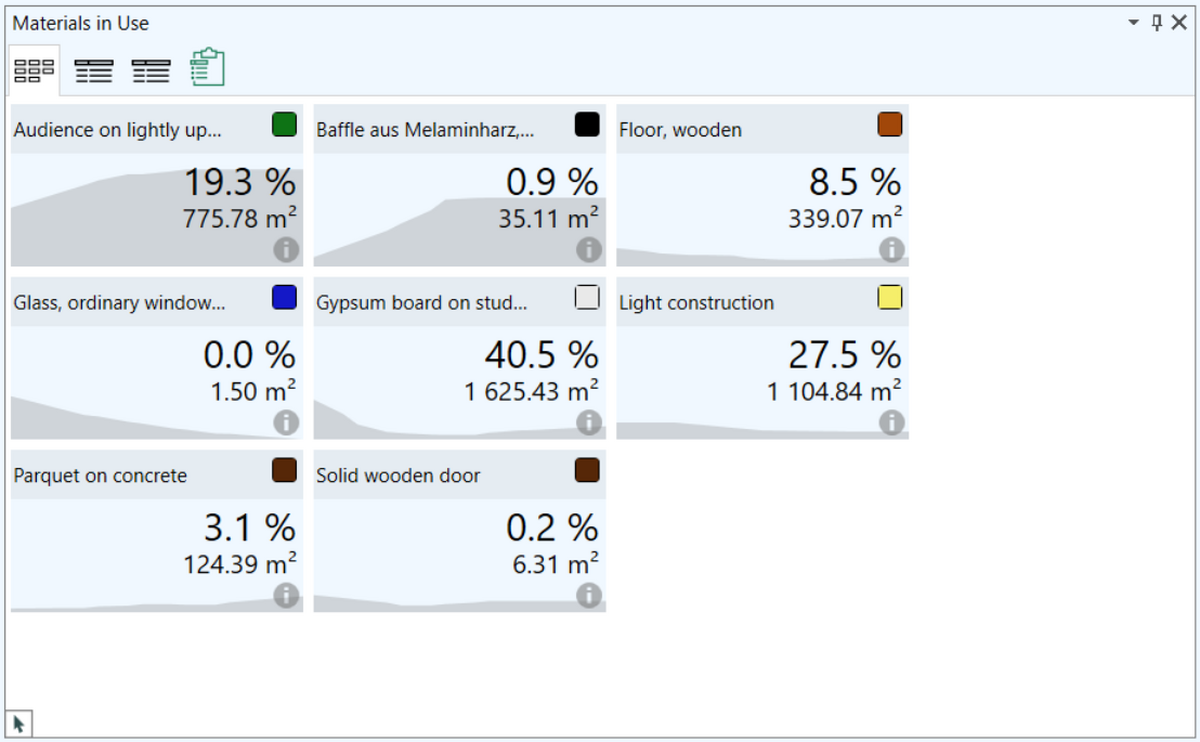

The materials in use can be visualized as a table, which can easily be exported for insertion in reports. Material changes for all surfaces of a material can be made with a single click and the effects are directly visible, e.g. in the RT or average absorption displays.

The 3D view, the table and all other windows are linked using color highlighting so that material assignments can be displayed and reviewed interactively.

First validation

The Acoustic Parameters Window provides an overview of all quantities needed for subsequent acoustic calculation and analyses. These parameters include:

From here, an initial validation can be started to check whether the initial assumptions, e.g. regarding the RT, are correct. It can provide information on whether the geometry or material selection need to be adjusted before running a simulation. All input values can be modified easily. Dependent results are immediately updated and visualized.

Having all these parameters available at a glance makes it easy to monitor them throughout the entire evaluation process, beginning with the rough first validation to all stages of optimization.

Viewing and calibrating the reverberation time

One of the primary challenges in room acoustics is selecting appropriate materials for a simulated model to ensure that the predicted reverberation time closely matches measured data.

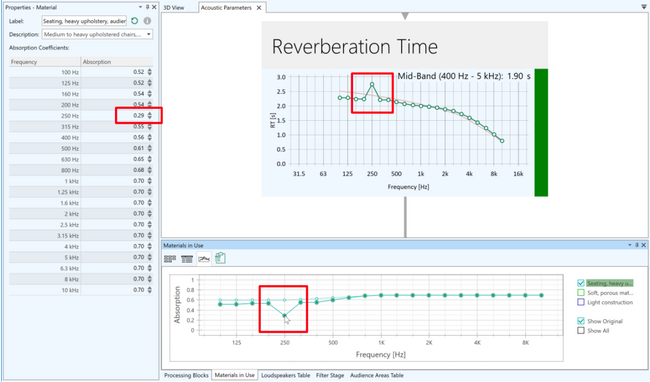

In EASE 5, the Acoustic Parameters window provides tools to assess the reverberation time (RT) of a room, displaying the calculated Eyring RT. If measured RT data is available, the simulation can be calibrated by adjusting the material properties so that the calculated RT aligns with the measured values.

The combination of the Acoustic Parameters and Materials in Use windows allows for precise matching of the model’s Eyring RT. The Acoustic Parameters window (upper graph) displays the measured RT as a light brown curve and the calculated RT as a green curve. Adjustments to the model can be made using the curve editor of the Materials in Use window (lower graph) or by modifying values in the Material Properties window (left panel), enabling users to fine-tune the calculated RT to match the measured RT. In the Materials in Use window, both the modified absorption curves (solid lines) and the original absorption curves (dashed lines) are displayed for comparison.

Although materials in the database are typically derived from professional laboratory measurements, their acoustic performance may differ when applied in real environments due to factors such as spacing, filling, boundary effects, or deviations from published data. For example, adjusting the absorption spectrum can compensate for differences in spacing between primary and secondary structures.

Starting the simulation

All these preparations and initial adjustments are aimed at creating an accurate acoustic room model that can be used as the basis for the room acoustic simulation employing highly accurate and proven simulation methods. Depending on the project requirements and expectations, the appropriate method can be chosen.

The use of cutting-edge technologies makes EASE 5 AFMG's innovative and powerful tool for analyzing, understanding and optimizing the acoustics of a venue. The new platform of EASE 5 enables more efficient working and achieving better results which is valuable for both decision-making and planning.